Multi Reactor Temperature Control Unit

ZLF -45℃~250℃- Heating Power25kW~80kW

- Power range2.3kW~10.5kW

- Material accuracy±1℃

- Heating typeWith “H”

- Heat exchange area3.5㎡~20㎡

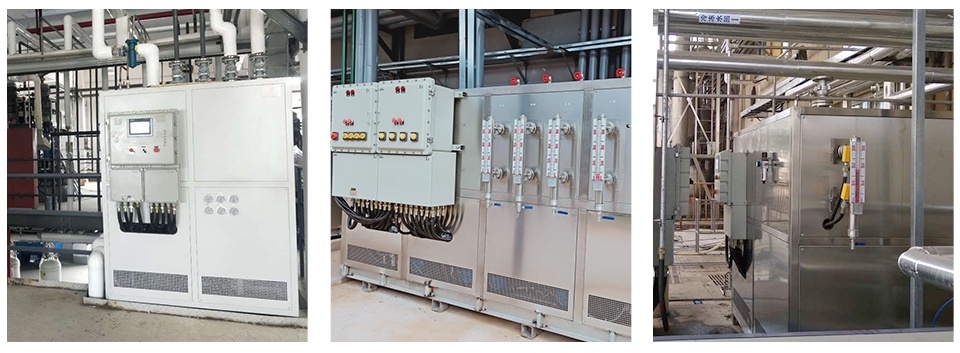

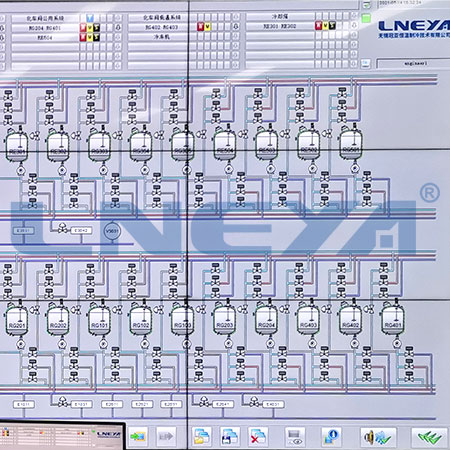

Chemical synthesis process control system

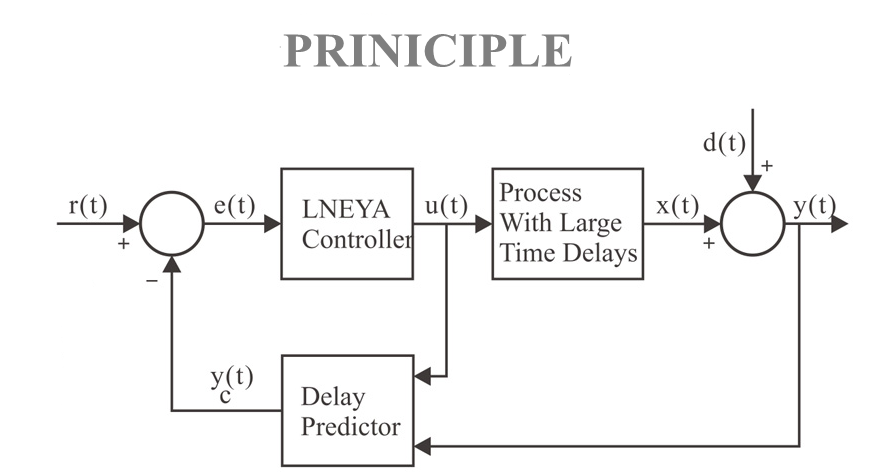

DCS automatic control system applies computer control technology, which can make the process operation and parameters of pharmaceutical production scientifically, effectively and strictly monitored and controlled, and realize the continuity and automation of pharmaceutical production.

Establish a full-process quality control system for pharmaceutical production to achieve full-process quality management from raw materials to finished products, making the pharmaceutical production process digital and standardized, with data traceability and early warning functions, and comprehensively improving the quality control level of pharmaceutical production.

WhatsApp 086 13912479193

Wechat 086 15152266993

Recommended Products

SUNDI -80℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.3kW~80kW Power range 7.5kW~150kW

SUNDI -60℃~250℃

Cooling capacity 0.25kW~60kW Heating Power 2.5kW~60kW Power range 5kW~95kW

SUNDI -25℃~200℃

Cooling capacity 1kW~200kW Heating Power 2.5kW~200kW Power range 4kW~260kW

UC 50℃~300℃

Heating Power 3.5kW~130kW Cooling power 1kW~130kW Power range 5kW~136kW

WTD -20℃~300℃

Heating Power 38kW~50kW Cooling capacity 12kW~50kW

WTD -70℃~200℃

Heating Power 38kW~50kW Cooling capacity 12kW~50kW

SR -120℃~250℃

Heating Power 25kW~80kW Power range 2.3kW~10.5kW Material accuracy ±1℃

HRT -45℃~250℃

Heating Power 2.5kW~15kW Cooling capacity 0.25kW~15kW Power range 4.5kW~25kW

loading…

已经是到最后一篇内容了!

Chillers (Biochemistry Pharmaceutical Process)

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA