Get chiller related information TCU Air Cooled Chillers Recirculating Chiller Dynamic Temperature Control Systems 产品分类菜单

Temperature range -120℃~250℃; Material Temperature Accuracy±0.1℃

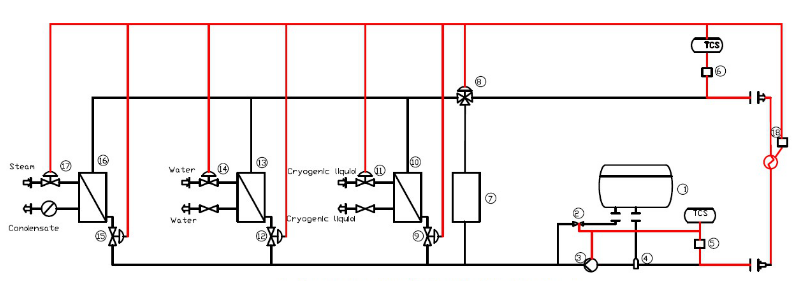

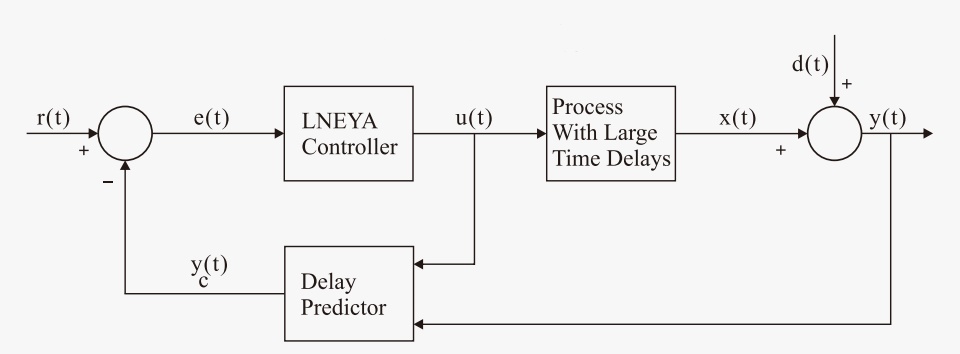

TCU temperature control system integrates existing thermal energy (such as steam, cooling water, and ultra-low temperature liquids – the “primary system”) infrastructure into a single fluid system or secondary loop used to control the temperature of process equipment. This completes the flow of only one type of heat conducting liquid into the jacket of the reaction vessel (instead of directly introducing steam, cooling water, or ultra-low temperature liquid), and controls the temperature of the entire reaction process through computation.

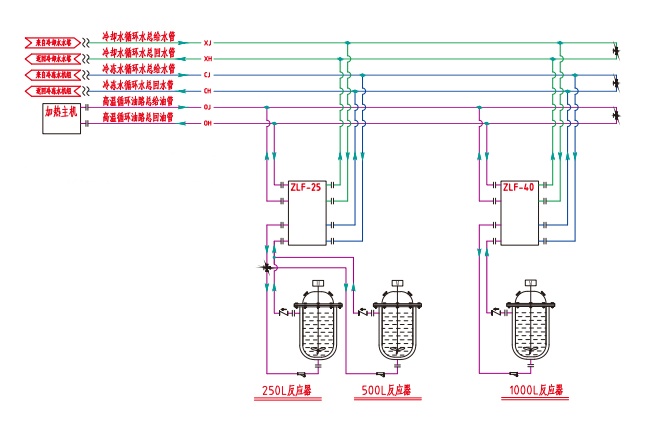

One host can control 2-20 reaction vessels of different sizes and materials. The TCU temperature control unit is a special device used to solve precise temperature control in the chemical and pharmaceutical industry, to meet the temperature control of intermittent reactors or the heating, cooling, and constant temperature system of continuous process.

Heating Power 25kW~80kW Power range 2.3kW~10.5kW Material accuracy ±1℃

Heating Power 25kW~80kW Power range 2.3kW~10.5kW Material accuracy ±1℃

loading…

已经是到最后一篇内容了!

DCS automatic control system applies computer control technology, which can make the process operation and parameters of pharmaceutical production scientifically, effectively and strictly monitored and controlled, and realize the continuity and automation of pharmaceutical production.

Establish a full-process quality control system for pharmaceutical production to achieve full-process quality management from raw materials to finished products, making the pharmaceutical production process digital and standardized, with data traceability and early warning functions, and comprehensively improving the quality control level of pharmaceutical production.

Scan QR code

+86 18914253067

18914253067

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)