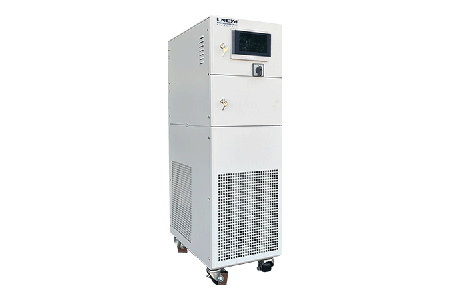

Get chiller related information TCU Air Cooled Chillers Recirculating Chiller Dynamic Temperature Control Systems 产品分类菜单

LT -80℃~30℃

Cooling Capacity 0.4kW~14kW

Temperature accuracy ±0.5℃

LTZ -115℃~90℃

Cooling capacity 0.6kW~2.8kW

Temperature accuracy ±0.5℃

FLTZ -100℃~90℃

Cooling capacity 1.5kW~40kW

Temp accuracy ±0.1℃

KRY -40℃~100℃

Heating capacity 2.5kW~38kW

Cooling capacity 1.8kW~60kW

LT -80℃~30℃

| Model | LT 10℃~30℃ | LT-25℃~30℃ | LT -45℃~30℃ | LT -60℃~-30℃ | LT -80℃~-40℃ |

| Cooling Capacity | 3KW~14KW | 1.5KW~5KW | 1.6KW~4.8KW | 0.7KW~4.8KW | 0.4KW~2.5KW |

| Flow Control | 30L/min~50L/min | ||||

| Refrigerant | R-134A / R407C | R-404A / R507C | R-404A / R507C | R-404A/R23 | R-404A/R23 |

| Temp control accuracy | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| Cooling capacity | 3KW~14KW@15℃ | 1.5kw~5kw@-15℃ | 0.7kw~2.5kw@-35℃ | 1.3kw~4.8kw@-40℃ | 0.7kw~2.5kw@-60℃ |

LTZ -115℃~30℃

| Temp Range | LTZ -40℃~90℃ | LTZ 5℃~30℃ | LTZ -25℃~30℃ | LTZ -45℃~20℃ | LTZ -60℃~-30℃ | LTZ -80℃~-50℃ | LTZ -115℃~-80℃ |

| Cooling Capacity | 0.7KW~11.5KW | 23KW~300KW | 7KW~117.5KW | 2.85KW~61.56KW | 4.9KW~93.2KW | 3.7KW~78.5KW | 0.6KW~2.8KW |

| Heating Power | 2.5kW~10KW | ||||||

| Temp control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ |

| Temperature feedback | Temperature feedback PT100 (inlet temperature, outlet temperature) | ||||

| Compressor | Highly, Mitsubishi, Panasonic and other compressors | ||||

| Evaporator | Plate Heat Exchanger | ||||

| Operation panel | 4.3-inch color touch screen displays set temp and measured temp, records temp curve, and exports data in Excel format | ||||

| Safety protection | Self-diagnosis function; refrigerator overload protection; high and low pressure sensors, overload relays, thermal protection devices and other safety protection functions |

||||

| Power | AC220V / AC380V/ AC460V | ||||

| Shell material | Cold rolled sheet (REL7035) | ||||

| Communication protocol | Communication protocol MODBUS RTU protocol RS485 interface | ||||

FLTZ -100℃~90℃

| Model | FLTZ Single Channel Series | Multi-channel Series | Heat Exchange Series ETCU |

| Temp Range | -45℃~+90℃ | -45℃~+100℃ | 5℃~+90℃ |

| Cooling Capacity | 1KW~40KW | 2KW~6KW | 5KW~300W |

| Temperature control accuracy | ±0.05℃ | ±0.05℃ | ±0.05℃ |

| Cooling water flow @20℃ | 1.5m³/h~9m³/h | 1.2m³/H~10.2m³/H | 1.5m³/H~8m³/H |

| FLTZ series | 5℃~90℃ | -25℃~90℃ | -45℃~90℃ | -80℃~+90℃ | -100℃~+90℃ |

| Temperature control accuracy | ±0.05℃ | ±0.05℃ | ±0.05℃ | ±0.05℃ | ±0.05℃ |

| Cooling capacity | 6KW~40KW @10℃ | 2KW~15KW @-15℃ | 1KW~8KW @-35℃ | 0.6KW~3KW @-70℃ | 1.5KW~3KW @-90℃ |

| Cooling water flow @20℃ | 1.5m³/h~9m³/h | 1.2m³/H~10.2m³/H | 1.5m³/H~8m³/H | 1.8m3/h~6m3/h | 50L/min~100L/min |

| Temperature feedback | Temperature feedback PT100 (inlet temperature, outlet temperature) | ||||

| Compressor | Highly, Mitsubishi, Panasonic and other compressors | ||||

| Evaporator | Plate Heat Exchanger | ||||

| Operation panel | 4.3-inch color touch screen displays set temp and measured temp, records temp curve, and exports data in Excel format | ||||

| Safety protection | Self-diagnosis function; refrigerator overload protection; high and low pressure sensors, overload relays, thermal protection devices and other safety protection functions |

||||

| Power | AC220V / AC380V/ AC460V | ||||

| Shell material | Cold rolled sheet (REL7035) | ||||

| Communication protocol | Communication protocol MODBUS RTU protocol RS485 interface | ||||

KRY -40℃~100℃

| Model | KRY -20℃~+100℃ | KRY -40℃~+100℃ | KRY -20℃~+100℃ 6S | KRY -40℃~+100℃ 6S | KRY -40℃~+100℃ 2T | KRY 0℃~+100℃ | KRY 0℃~+100℃ 6S | KRY -40℃~+100℃ 2T |

| Temp control accuracy | ±0.3℃ | |||||||

| Flow rate accuracy | ±0.2 L/min | |||||||

| Heating capacity | 5.5KW~38KW | 5.5KW~60KW | 15KW~38KW | 15KW~38KW | 7.5KW*2~38KW*2 | 2.5KW~38KW | 15KW~38KW | 2.5KW*2~38KW*2 |

| Cooling capacity | 2.8KW~38KW | 1.2KW~60KW | 10KW~60KW | 5KW~60KW | 1.8KW*2~60KW*2 | 1.8KW~60KW | 18KW~60KW | 1.8KW*2~60KW*2 |

| Power 380V50HZ | 11KW~45KW | 10KW~84KW | 36KW~75KW | 38KW~82KW | 28KW~158KW | 4.5KW~61KW | 38KW~82KW | 9KW~120KW |

| Temperature feedback | Temperature feedback PT100 (inlet temperature, outlet temperature) | ||||

| Compressor | Highly, Mitsubishi, Panasonic and other compressors | ||||

| Evaporator | Plate Heat Exchanger | ||||

| Operation panel | 4.3-inch color touch screen displays set temp and measured temp, records temp curve, and exports data in Excel format | ||||

| Safety protection | Self-diagnosis function; refrigerator overload protection; high and low pressure sensors, overload relays, thermal protection devices and other safety protection functions |

||||

| Power | AC220V / AC380V/ AC460V | ||||

| Shell material | Cold rolled sheet (REL7035) | ||||

| Communication protocol | Communication protocol MODBUS RTU protocol RS485 interface | ||||

| Reaction kettle | Fermentation tank | Microreactor | Tubular reactor |

| Vacuum chamber | Freeze-drying machine | Multiphase reactor | Tower reactor |

| Industrial oil treatment | Gas chromatograph | Rotary evaporator | Pilot plant |

| Injection water system | Pharmaceutical water system | Neutralization reaction | decomposition reaction |

| oxidation reaction | Polymerization reaction | Crystallization reaction | Fermentation reaction |

| Oil decomposition | Concentration reaction | Extraction System | Test Bench |

| Gas Condensation | Semiconductor Testing equipment | Fab equipment | AOI system CMOS/CCD |

| Tool machine | Cooling tower | Battery test cooling | Laboratogy research |

| MRI | ATE | CO2 equipment | 2 stage chemical cooling |

| Mixer | Mechanical lathe | Clean room | Laboratory Glass Reactor |

We use a variety of internationally renowned accessories, all of which can be customized for your needs, such as compressors, evaporators, heat exchangers, circulation pumps, controllers, expansion valves and shell materials, etc.

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements.

No matter how many tons of chiller you need, we can create the best solution.

We can create a custom solution for temperatures from -150℃ to +350℃.

Custom temperature ranges for specific industries.

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers.

Regardless of the type of refrigeration compressor, we can design it according to your requirements.

We offer a very wide range of cooling capacities for various industries.

LNEYA supports custom designs and gives quotes within 24 hours.