KRY 0℃~100℃

Vehicle / Battery test temperature simulation equipment- Heating Power2.5kW~38kW

- Cooling capacity1.8kW~60kW

- Power range38kW~82kW

- Temperature accuracy±0.3℃

- Flow rate output2~50 L/min

- Flow rate accuracy±0.2 L/min

- RefrigerantR404A/R507C/R125/N40

Temperature range is 0℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

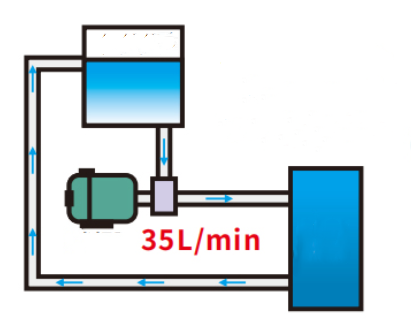

Equipped with a powerful circulation pump while ensuring the delivery of highly viscous liquids.

Control the flow output with variable frequency regulation or proportional control valve to achieve high precision control total range 5%~100% adjustment.

The testing part is connected to a platform adapter, and the thermal mediumpasses through the testing part to provide a high and low temperatureenvironment. The testing part goes through a temperature change to check itsperformance.The temperature change can be recorded.

The tested object is attached to a test platform adapter.

The inside of the part was cooled and heated by an aqueous solution of ethylene glycol.

The test component needs to go through a specific temperature profile and record changes in temperature.

When performing a tolerance test, it usually takes an infinite loop.

| Model | KRY-25 | KRY-55 | KRY-75 | KRY-A10 | KRY-A15 KRY-A15W |

KRY-A25 KRY-A25W |

KRY-A38W | KRY-A60W | |

| Temp Range | 0℃~+100℃ | ||||||||

| Temp control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Temp feedback | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | |

| Temp display | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | |

| Flow rate output | 2~20 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 5~50 L/min | 5~50 L/min | |

| Flow rate accuracy | ±0.2 L/min | ||||||||

| Heating capacity | 2.5kW | 5.5kW | 7.5kW | 10kW | 15kW | 15kW | 25kW | 38kW | |

| Cooling capacity | 100℃ | 2.5kW | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW |

| 20℃ | 2.5kW | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 5℃ | 1.8kW | 3.8kW | 5.2kW | 7kW | 11kW | 18kW | 27kW | 42kW | |

| Connection size | G3/4 | G3/4 | G3/4 | G3/4 | G3/4 | G3/4 | G3/4 | G3/4 | |

| Water-cooled type W @ 25℃ | 3200L/H ZG1 |

6000L/H G1 1/4 |

9000L/H DN40 |

15000L/H DN50 |

|||||

| Power 380V50HZ | 4.5kW220V | 8.5kW | 11.5kW | 16kW | 18kW | 28kW | 40kW | 61kW | |

| Dimension cm | 50*85*145 | 55*100*175 | 55*100*175 | 70*100*175 | 80*120*185 | 100*150*185 | 100*150*185 | 100*150*185 | |

| Weight | 220kg | 250kg | 280kg | 320kg | 360kg | 620kg | 890kg | 1300KG | |

| Model | KRY-A25W/6S | KRY-A38W/6S | KRY-A60W/6S | |

| Temp Range | 0℃~+100℃ | |||

| Temp control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Temp feedback | Pt100 | Pt100 | Pt100 | |

| Temp display | 0.01k | 0.01k | 0.01k | |

| Flow control accuracy/Group | 2~25 L/min | 2~25 L/min | 2~25 L/min | |

| Flow rate accuracy/group | ±0.2L/min | |||

| Number of fuid output groups | 6 groups | 6 groups | 6 groups | |

| Pressure control/group | 0.2bar~2.5bar | 0.2bar~2.5bar | 0.2bar~2.5bar | |

| Heating capacity | 15kW | 25kW | 38kW | |

| Cooling capacity | 100℃ | 25kW | 38kW | 60kW |

| 20℃ | 25kW | 38kW | 60kW | |

| 5℃ | 18kW | 27kW | 42kW | |

| Water-cooled type W @ 20℃ | 6000L/H DN32 |

9000L/H DN40 |

15000L/H DN50 |

|

| Power 380V50HZ | 38kW | 55kW | 82kW | |

| Dimension cm | 200*145*205 | 200*145*205 | 200*145*205 | |

| Weight | 900kg | 1200kg | 1950kg | |

| Model | KRY-25/2T | KRY-55/2T | KRY-75/2T | KRY-A10/2T | KRY-A15W//2T | KRY-A25W/2T | KRY-A38W/2T | KRY-A60W/2T | |

| Temp Range | 0℃~+100℃ | ||||||||

| Temp control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Temp feedback | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | |

| Temp display | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | |

| Flow rate output | 2~20 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 5~50 L/min | 5~50 L/min | |

| Flow rate accuracy | ±0.2 L/min | ||||||||

| Heating capacity | 2.5kW*2 | 5.5kW*2 | 7.5kW*2 | 10kW*2 | 15kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | |

| Cooling capacity | 100℃ | 2.5kW*2 | 5.5kW*2 | 7.5kW*2 | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | 60kW*2 |

| 20℃ | 2.5kW*2 | 5.5kW*2 | 7.5kW*2 | 10kW*2 | 15kW*2 | 25kW*2 | 38kW*2 | 60kW*2 | |

| 5℃ | 1.8kW*2 | 3.8kW*2 | 5.2kW*2 | 7kW*2 | 11kW*2 | 18kW*2 | 27kW*2 | 42kW*2 | |

| Connection size | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | |

| Water-cooled type W @25℃ | 5600L/H DN32 |

10000L/H DN40 |

17000L/H DN50 |

24000L/H DN65 |

|||||

| Power 380V50HZ | 9kW | 19kW | 23kW | 29kW | 34kW | 52kW | 80kW | 120kW | |

| Dimension cm | 55*100*175 | 70*100*175 | 80*120*185 | 100*150*185 | 100*150*185 | 200*145*205 | 200*145*205 | 250*145*225 | |

| Weight | 260KG | 320KG | 400KG | 580KG | 750KG | 1250KG | 1600KG | 2400KG | |

| Compressor | Brand Copeland | ||||||||

| Throttle type | Electronic expansion valve | ||||||||

| Oil separator | Emerson/GUANYA | ||||||||

| Dry filter | Danfoss | ||||||||

| Evaporator | Plate heat exchanger | ||||||||

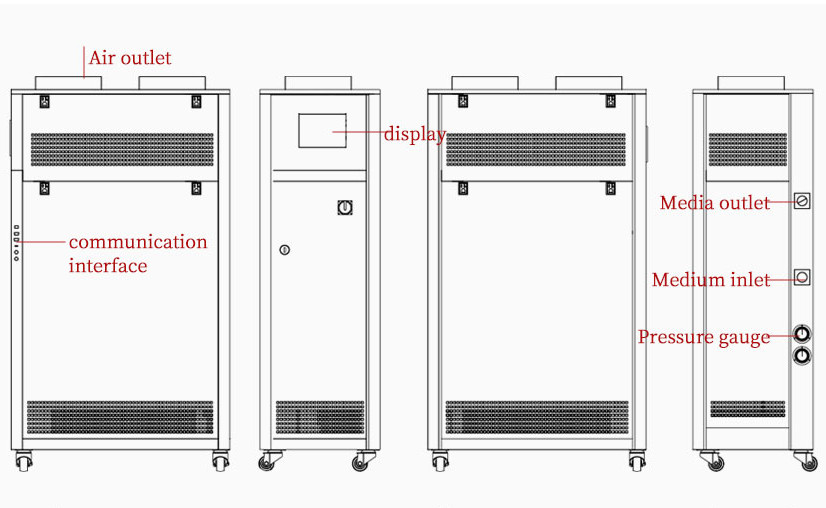

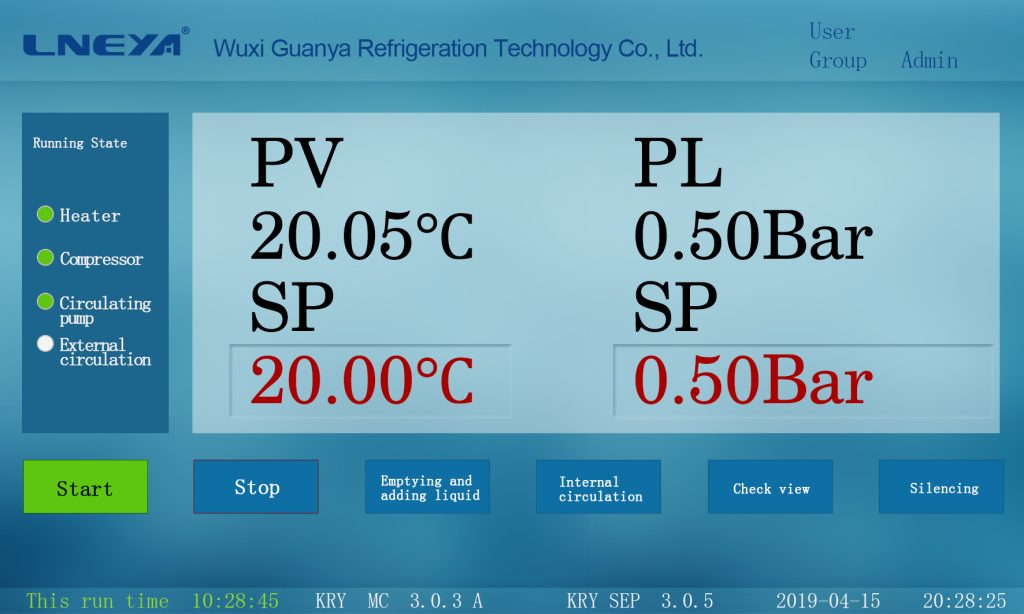

| Input display | 7-inch color touch screen \ PLC controller | ||||||||

| Program Editor | 5 programs, each program can edit 40 steps | ||||||||

| Communication | Modbus RTU protocol RS485 interface, optional CAN communication bus, Ethernet interface TCP/IP protocol | ||||||||

| Safety protection | With self-diagnosis function; Refrigerator overload protection; High pressure switch, overload relay, thermal protection device, high temperature protection, sensor fault protection and other safety functions | ||||||||

| Closed circulation system | The whole system is a fully closed system, there will be no oil mist at high temperature, the system in operation will not because of high temperature pressure rise, low temperature automatically add heat conduction medium |

||||||||

| Condenser(W) | Paris/Shenshi tube type heat exchanger | ||||||||

| Condenser(A) | Copper tube aluminum fin heat exchanger (upper outlet form) | ||||||||

| Optional | 220V 60HZ three-phase 460V 60HZ three-phase | ||||||||

| Optional | Higher precision control of temperature, flow rate, and pressure | ||||||||

| Optional | Automatic antifreeze system | ||||||||

| Optional | Automatic liquid recovery system | ||||||||

| Case material | Cold rolled sheet (REL7035) | ||||||||

Multi channel independent temperature control

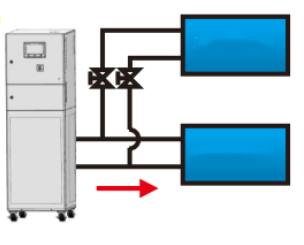

The system adopts LNEYA PLC control, with simple menu navigation, a 7 inch color large screen, and comprehensive and multifunctional image display of important data information. The newly added safety measures ensure continuous unmanned operation. All relevant operating status data is continuously monitored and visualized on the touch screen. It supports independent control of one to many channels, and each group can be set independently.

Variable frequency regulation

The variable frequency pump can adjust the circulating liquid pressure and flow rate, achieving high-precision control of 5%~100% of the total range adjustment.

Client A

Client B

By using a variable frequency pump, the motor speed can be controlled at the appropriate value corresponding to the required pressure.

Test temperature of main test items of vehicle electronics:

IC test conditions for locomotives: -40℃~125℃, wind blowing, sun exposure, high vibration;

Instrument panel operation test test conditions: -40℃~85℃;

Motor controller test conditions: operating test temperature: 40 ℃ ~ 110 ℃;

Satellite positioning (GPS) Test conditions: high temperature operation test temperature: 85℃; low temperature operation test temperature: -40℃;

Compound vibration: -40℃~80℃;

Obviously the best solution is for the test house to have temperature simulation system equipment.

Motor and motor controller

Motor coroller durabilitytest, motor and motorcontroller bracket

Charge point test

On load charging experiment and charging communication interactive test

OBC/DC-DC

Model test, power test. Durability test

Power battery system

Battery pack charge and discharge test, fuel cell test

You can send us an inquiry via WhatsApp or WeChat.

8613912479193

8615152266993

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA